Pipe Stiffness and Burst Pressure Assessment Of Din 250

Report Pe Pipe

Introduction

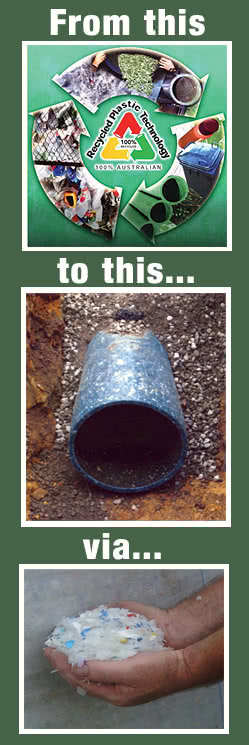

This report details the determination of pipe stiffness

and burst pressure carried out on a DN 250 RPT Green Pipe

(recycled PE pipe) supplied by RECYCLED PLASTICS TECHNOLOGY

PTY LTD. Two 1 metre lengths and two 800 mm lengths flanged

on one end and sealed on the other end were supplied for the

assessment. The pipes were marked 45kg and 5Okg, and were

mottled green in colour with a coarse texture from the raw

material, which was chopped polyethylene bottle waste.

The following identifications were assigned for the pipe

samples:

- PDA 001019 1 45 kg pipe

- PDA 001019 2 50 kg pipe

Pipe Stiffness Assessment Experiments

300 mm in lengths were prepared from the samples and tested

in accordance with AS/NZS 1462.22:1997.

The pipe lengths supplied were marked on the outside with

a marking line drawn parallel to the pipe longitudinal axis

at 120 degrees apart around the circumference. Each mark was

identified as A, B and C respectively. Each specimen was then

cut to a length of 300 ± 10 mm and measurements taken

for internal diameter (ID) and specimen length at different

positions located around the circumference of the pipe specimen.

The specimens were then placed between two steel loading plates

and deflected at a rate of 20 ± 2 mm/min until the

deflection corresponding to 5 % of the ID was reached at each

of the three marked (fines. Load and displacement measurements

were continuously recorded through out the test.

Results:

The deflection of the pipe specimen in each case was taken

to be the movement of the crosshead on the compression testing

machine. Table 1 shows loads at 5% deflection and the calculated

pipe stiffness values for each of the pipe specimens tested.

The pipe stiffness values were calculated in accordance with

AS/NZS 1462.22: 1997, section 8.

Table 1. Deflection results and calculated stiffness values

| Specimen No. |

Pipe length

(mm) |

Average Inside

Diameter (mm) |

Force at 5%

Deflection

(NI300 mm) |

Stiffness at 5%

deflection

(N/m/m) |

| PDA00l019-1 |

298.8 |

247.47 |

1148 |

6162.9 |

| PDA00l019-2 |

298.95 |

242.76 |

1541 |

8427.6 |

Source: CSIRO Graham Road (PO Box 56), Hlghett, Victoria

3190, Australia, www.dbce.csiro.au.

Based on this relationship between stiffness and SDR, the

minimum wall thicknesses for pipes of different dimensions

and stiffness classes are presented in Table 2.

Table 2. Wall thickness projections for pipes of different

stiffness classes

| Stiffness |

SDR |

Wall thickness of pipe |

| N/m/m |

SN |

|

OD200 |

Od250 |

OD300 |

OD350 |

| 2000 |

|

40.4 |

4.49 |

6.18 |

7.42 |

8.65 |

| 3000 |

|

37.7 |

5.30 |

6.63 |

7.95 |

9.28 |

| 4000 |

4 |

35.0 |

5.71 |

7.14 |

8.57 |

10.00 |

| 5000 |

|

32.3 |

6.20 |

7.74 |

9.29 |

10.84 |

| 6000 |

6 |

2906 |

6.77 |

8.46 |

10.15 |

11.84 |

| 7000 |

|

26.8 |

7.45 |

9.32 |

11.18 |

13.04 |

| 8000 |

8 |

24.1 |

8.30 |

10.37 |

12.44 |

14.52 |

| 9000 |

|

21.4 |

9.35 |

11.69 |

14.03 |

16.37 |

| 10000 |

10 |

18.7 |

10.72 |

13.40 |

16.07 |

18.75 |

| 11000 |

|

15.9 |

12.55 |

15.68 |

18.82 |

21.96 |

| 12000 |

12 |

13.2 |

15.13 |

18.92 |

22.70 |

26.48 |

| 13000 |

|

10.5 |

19.06 |

23.83 |

28.59 |

33.36 |

| 14000 |

14 |

7.8 |

25.74 |

32.18 |

38.61 |

45.05 |

| 15000 |

|

5.0 |

39.63 |

49.54 |

59.45 |

69.36 |

| 16000 |

16 |

2.3 |

86.10 |

107.82 |

129.14 |

150.67 |

These projections are based on 4 determinations, two of two

of which were based on pipes of indifferent quality in terms

of wall thickness uniformity. Therefore the wail thicknesses

presented in Table 2 should be treated as a guide only, until

more stiffness determinations have been carried out, and accurate

stiffness values are available from production quality pipe

for a range of SDRs.

Conclusion

The 45kg (PDA 001019 1 ) meets the requirement of stiffness

class SN6 and the 5Okg pipe (PDA OOI019 2) meets the requirement

of stiffness class SN8. Based on these results and previous

test results, the wall thickness projections for different

SN classes and for several pipe sizes are presented.

|